13 min read

Is your team vibe feeling off? How to reset your team dynamics

As teams return from their summer (or winter) break, you may notice subtle shifts in your team’s energy. Even if the end of year was positive, a new...

Develop leaders, strengthen executive teams and gain deep insights with assessments designed to accelerate trust and performance.

Transform how your leaders think and perform with keynotes that spark connection, trust and high-performance cultures.

Explore practical tools, thought-leadership and resources to help you build trusted, high-performing teams.

Trustologie® is a leadership development consultancy founded by Marie-Claire Ross, specialising in helping executives and managers build high-trust, high-performing teams.

2 min read

Marie-Claire Ross : Updated on November 25, 2015

When it comes to warnings about potential dangers or giving people an important instruction on site, you have to rely on labels and signs to communicate. A sign's message can be communicated effectively with a picture that can be understood across all ages and languages (see Why Using Visuals in your Communication is so Important for more information on why visuals work so well).

When it comes to warnings about potential dangers or giving people an important instruction on site, you have to rely on labels and signs to communicate. A sign's message can be communicated effectively with a picture that can be understood across all ages and languages (see Why Using Visuals in your Communication is so Important for more information on why visuals work so well).

Multinationals employing thousands of workers from Boston to Bangkok and even small companies employing just a few, can benefit from a few key guidelines when creating signs, ensuring that messaging and communications are effective.

They are:

When checking your site for the relevance of current signs, ask yourself these questions:

If you answered, no to any of these questions. Then, it's time to replace your safety signs and labels.

Whether you’re a safety manager from Sydney or a facility manager from Forbes, consistent use of safety signs play a critically important role in reducing injuries and saving lives at industrial facilities.

Guest Blogger: Jack Rubinger, www.DuraLabel.com, has more than 20 years of safety and visual communications writing experience. For more information about this article, call 800-788-5572 or email jarubinger@graphicproducts.com.

13 min read

As teams return from their summer (or winter) break, you may notice subtle shifts in your team’s energy. Even if the end of year was positive, a new...

14 min read

The workplace is evolving at a pace few previous generations have seen and 2026 will mark a turning point. The Future of Work is blended, not hybrid....

5 min read

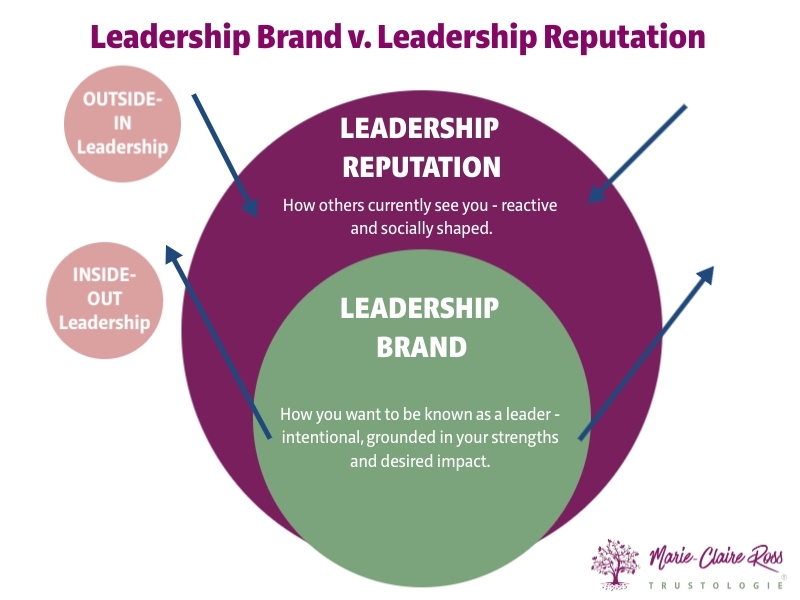

Many leaders jump into a leadership position excited by the opportunity to help others and perform at a higher level.

2 min read

Every mining company knows that a safe working environment for everyone, including sub-contractors, is the mine site’s responsibility – even if...

As mentioned in " How to Develop a Workplace Safety Messages Campaign" Part 1, marketing is the key to getting your safety messages heard and...